Hi @Spcbrn,

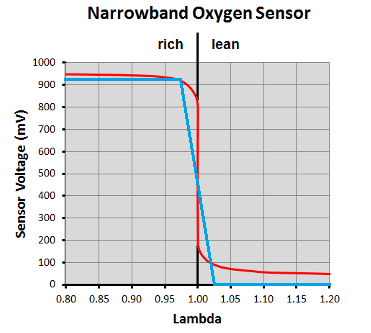

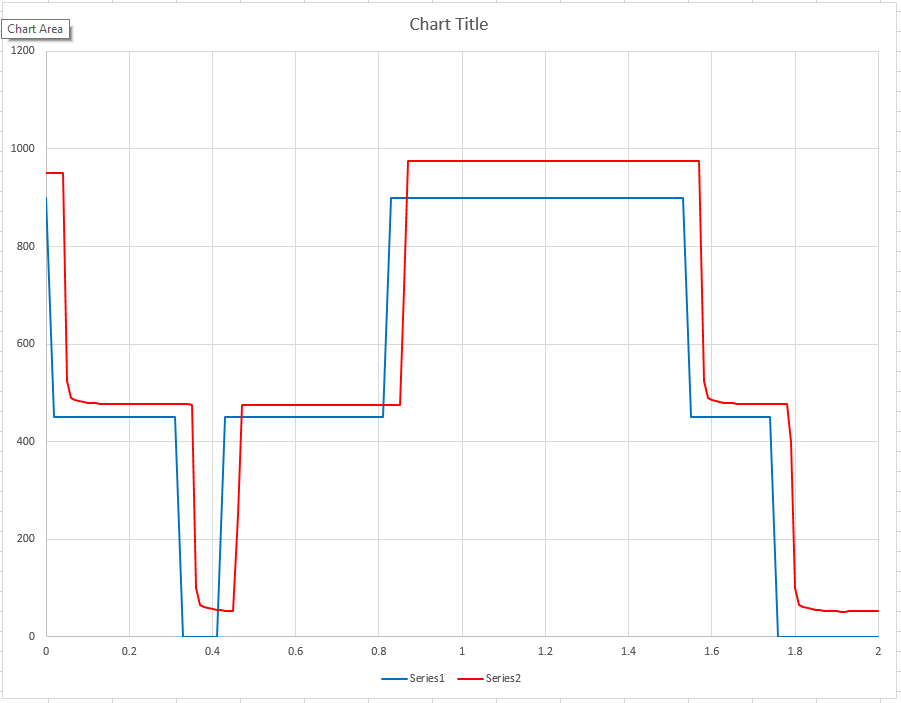

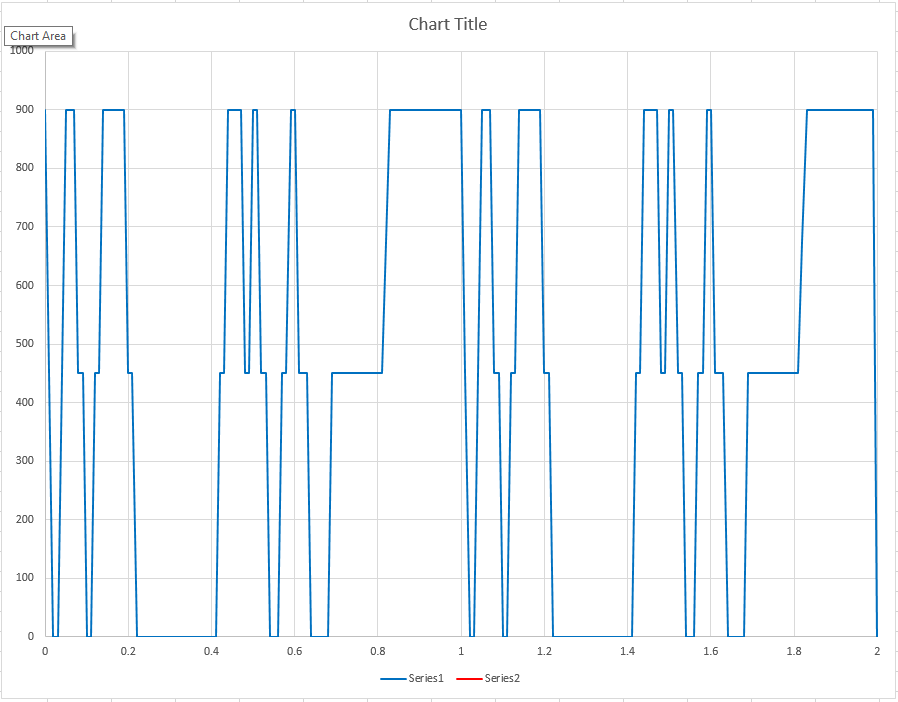

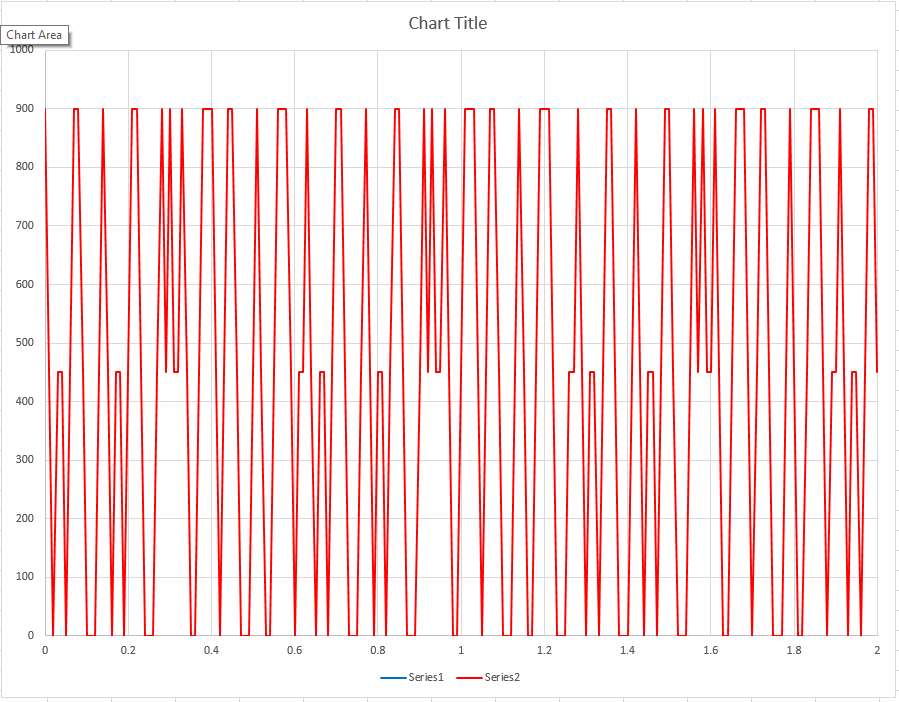

More or less, I programmed the 0-5V output with the USB serial commands as per the user instruction manual, using the commands set SETLAM5V to 0.99 and SETLAM0V to 1.00, with a resistor voltage divider. It worked well enough at first, but still get the check engine once in a while. Then I’ve tried to set them to 0.9999 and 1.0001 as per @toalan recommendations, and while it reported back 1.00 for both, it did work well enough to stop the check engine light from coming on, but not well enough to clear the permanent code, which will reset anyway, once I’m happy with my tune and put back the original narrowband sensor.

I’ve been tuning for months now, added bigger injectors (Don’t forget to tune the gas pump control module if you have a Trax, to better cope with the additional demand, I had to, gas pressure was dipping low when I went WOT), alcohol sensor, fine tuned the MAF sensor, then realized it was bad (huge hysteresis), replaced it, tuned it again, then tuned the VVE tables, then the virtual torque maps and accelerator demand, and then the tranny… It’s been a long process, but it’s way more aggressive now, yet have a better fuel efficiency when I drive normally.

Now I’m only using the wideband to monitor the tune, make sure everything runs fine as it should, in any temperature, in all conditions, once I’m satisfied, I will put the narrowband back and be done with it, if I’m ever done with it

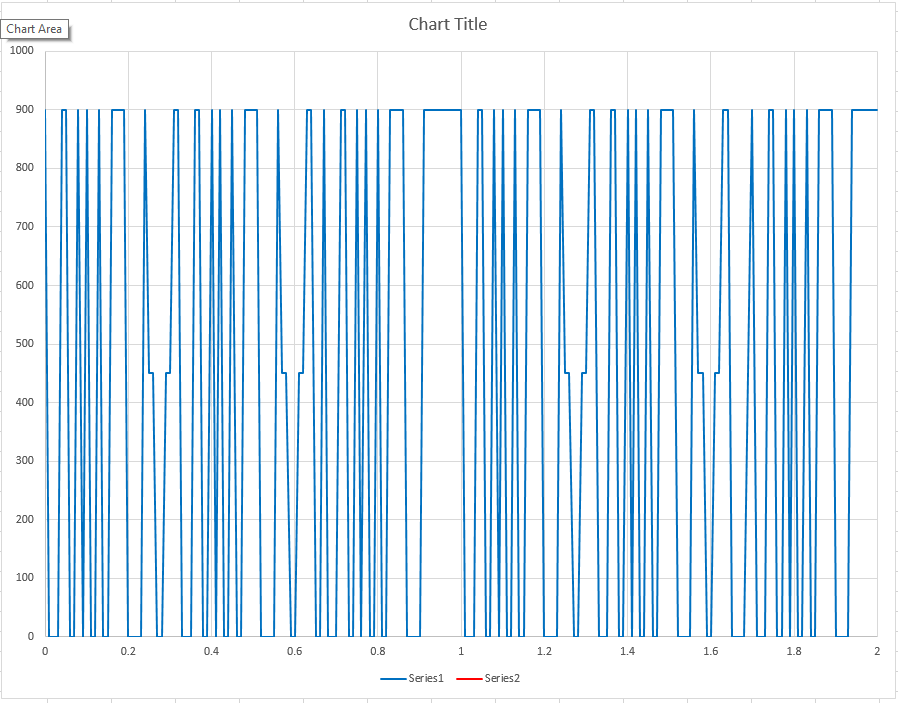

To hook it up, I plugged the 1200 Ohms resistor into the Analog output (screw #6), the 220 Ohms (what I had in stock) to the electronic ground (Screw #2), then soldered the other resistors ends together with the wire going to the ECU, which gave me the required signal.

You do need to know that I was using the CANBUS signal to read the real wideband sensor value from my MPVI3 with VCM Scanner (HP Tuners), so I didn’t mind sacrificing my analog output since I wasn’t using it for tuning and/or a gauge.

@toalan did mention that he would add better support for both the narrowband and wideband analog outputs in the next firmware, you should check with him what’s the ETA for those modifications.

Hope this helps,

Dr_Evil